Tel :

86-15905996312Email :

machine@hongancn.com

Tel :

86-15905996312Email :

machine@hongancn.comTrouble: When the melamine crockery compression machine is pressuring, the mold can not close or the pressure oil gauge is over 200.

Why and how to solve this problem?

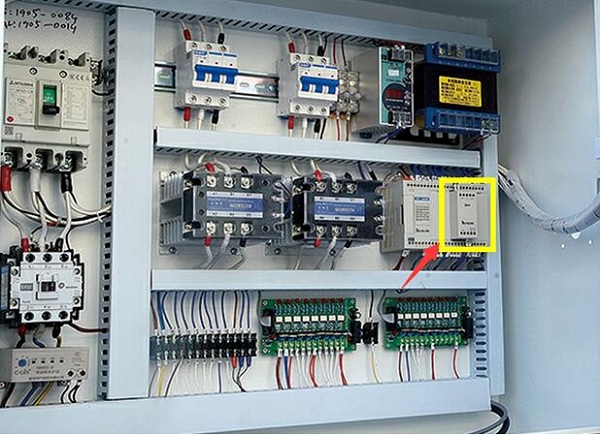

Troubleshooting method 1: Check whether the module is loose

Step 1: Turn off the power of the machine and pull out the module

Step 2: Re-insert the module and lock the two black lock blocks up and down

Step 3: Gently shake the module, to check if it is lock tightly and not moved.

Under normal circumstances, if the module is locked, it cannot be moved.

Step 4: Restart the power supply, press button of Curing (or any other buttons) to check whether the mold can be properly closed. If the mold can be closed normally, the problem is solved.

Troubleshooting method 2: If the module is not loose, then start to check the sensor on the machine stroking board.

For example, if starts the button of Curing, the machine pressurizes and the mold closes normally. But Press the button of Finishing agent (means Glazing), the machine pressurizes, and the mold can be closed, but the pressure exceeds 200 abnormally. Then correspondingly find the sensor of Finished agent slow-up on the stroking board, and check whether the corresponding sensor light is on when the machine is pressurized. If it is light-off, it means that the sensor needs to be adjusted upwards. When the machine is pressurized, the corresponding sensor light should be on for the pressure to work properly.

After adjusting up, the light is on when machine is pressuring, then the problem is solved.