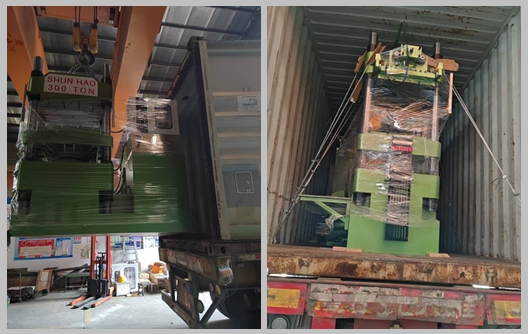

Customized Grey 600T Hydraulic Molding Machines Delivered

In early March, Shunhao Factory shipped two customized grey 600-ton hydraulic molding machines to meet a client’s production expansion needs. 600 ton molding machine is widely used for large melamine plates and trays, offer stable performance and high efficiency to boost the client’s capacity and competitiveness. As a professional melamine tableware machine and mold manufacturer, Shunhao wins trust with outstanding service, providing one-stop solutions for over 200 global factories. Choose Shunhao as your reliable partner for customized machines, molds and one-stop melamine production support. Contact us for more details: Tel: +86 15905996312 (Ms. Shelly) Email: machine@hongancn.com Shunhao Machinery — Your Trusted Melamine Production Partner with Thoughtful Service.

read more

ipv6 network supported

ipv6 network supported