Tel :

86-15905996312Email :

machine@hongancn.com

Tel :

86-15905996312Email :

machine@hongancn.comThe topic of the article today is about how to replace the new oil pump after the oil pump used in the melamine tableware compression machine has problems.

If the machine in use has the following conditions, you can check whether there is a problem with the oil pump:

1. When the machine is normally pressurized, the pressure display is abnormal or no pressure display;

2. When the machine is pressurized normally, the pressure has abnormal noise.

When the oil pump has problems and needs to be replaced, the cost of replacing the pump core is lower than that of replacing the entire set of oil pump. However, some molding machines need to replace the entire set of oil pump, and some only need to replace the pump core. It depends on the type of oil pump used by the machine.

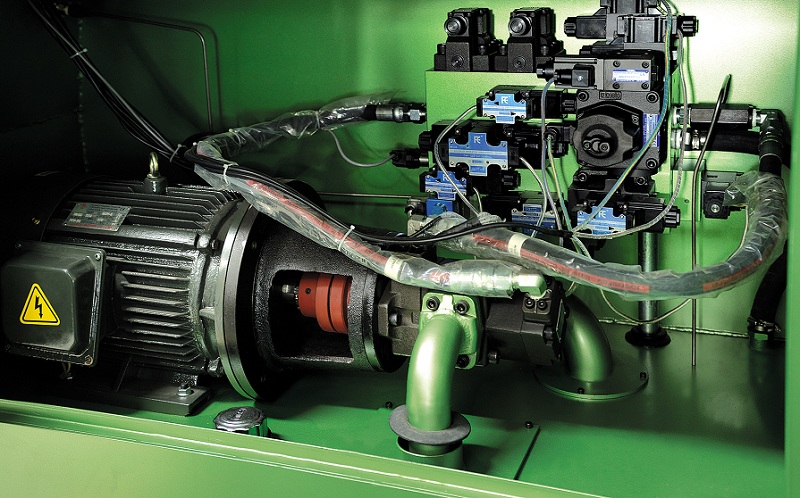

The raw material of melamine tableware is melamine powder, because of the powder form easily causes dust, the working environment is relatively harsh, and the requirements for the pump are relatively high. Therefore, the oil pumps widely used in melamine crockery molding machines mainly include vane pumps and gear pumps.

VANE PUMP GEAR PUMP

Gear pumps are used in most early melamine tableware machines. Because of its good sealing, Germany quality, it is favored by tableware machine manufacturers. However, there’s a problem: why many tableware factory owners mentioned one thing in common: the early molding machine has good quality and rarely problems, but the production is really slow. This is obviously a disadvantage.

Why is it slow in production?

Because the gear pump is completed by the meshing between the gears, the pressure cannot be too high. If it’s too high, the gears can easily get stuck. As a result, the gear pump does not work and the machine stops. So, you will find that the pressure of these machines should be reduced, and the pressure of small machines should not exceed 100 tons. When the pressure of the machine is less than the rated value, work slowly and the machine can run for a long time. However, the slow machine can't keep up with the requirements of the current development! What’s more, the quality of gear pumps on the market is uneven. It is easy to buy fakes at a high price, and some even break after 3 days.

Vane pump follows a centrifugal working principle. Although the sealing degree is not as good as the gear pump, the vane pump runs smoothly with the advantages of small pressure pulsation, small noise, compact structure, small size, large flow rate, and resistant to high pressure. Moreover, the maintenance cost of the vane pump is much lower than that of the gear pump, and it is easy to replace. Therefore, it becomes an ideal choice for high-speed molding machine

Shunhao Machines & Moulds Factory is using qualified quality vane pumps in order to improve the work efficiency for melamine tableware production, always concerns from the customer's point of view, keeping pace with the times.

When replacing the pump core, the most important point is to align the positioning pin inside, then put it in and lock it.

Of course, an oil pump does not determine the production speed of the machine, but it is one of the essential factors. Different types of oil pumps will have different connection holes, and the size of the holes is also fixed. If you buy a machine from the manufacturer, you have to follow the type of oil pump used by the machine. Therefore, please choose the machine supplier carefully. Though big brands affect, but more importantly, it is necessary to identify the practicality of the machine and the after-sales service capabilities of the manufacturer!

Shunhao Factory specializes in manufacturing melamine tableware making equipments that adapts to the times, not only maintaining quality, but also improving production efficiency for tableware factories!