Tel :

86-15905996312Email :

machine@hongancn.com

Tel :

86-15905996312Email :

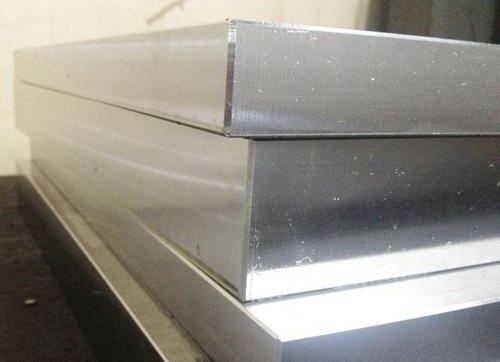

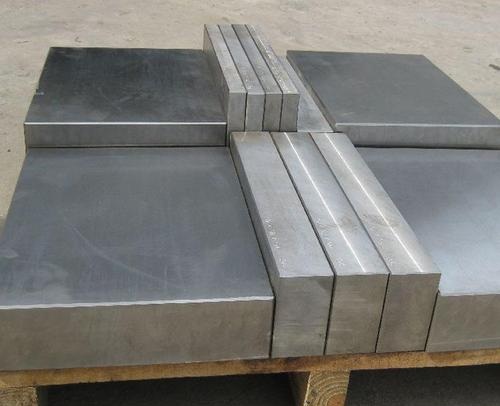

machine@hongancn.comDie steel is used to make cold die, hot forging die and die casting die steel. Moulds are the main processing tools for manufacturing parts in machinery manufacturing, radio instruments, motors, electrical appliances and other industrial sectors.

Die steel can be roughly divided into (cold work die steel), (hot work die steel) and (plastic die steel) 3 types, used for forging, stamping, cutting, die casting, etc. Due to the different purposes of various molds and complex working conditions, the steel used for molds should have high hardness, strength, wear resistance, sufficient toughness, and high hardenability and other technological properties according to the working conditions of the mold made by it.

1. Cold work dies include cold punching dies, wire drawing dies, drawing dies, stamping dies, thread rolling dies, thread rolling plates, cold forging dies and cold extrusion dies.

Cold work die steel should have high hardness, strength, wear resistance, sufficient toughness, and high hardenability and other process properties according to the working conditions of its manufacture.

Commonly used steels include high carbon low alloy steel, high carbon high chromium steel, chromium molybdenum steel, medium carbon chromium tungsten steel, etc.

2. Hot work die is divided into hammer forging, die forging, extrusion and die casting, including hot forging die, press forging die, stamping die, hot extrusion die and metal die-casting die.

Commonly used steels include chromium-manganese steel, chromium-nickel steel, chromium-tungsten steel, etc.

Under normal circumstances, hot work die steel can be selected for injection molding or extrusion molding die.

Cold work die steel can be used for thermoset molding and molds that require high wear resistance and high strength.

3. Plastic molds include thermoplastic molds and thermoset plastic molds.

For melamine mold steels, based on powder quality and cost considerations, the three widely used steels in the market are 718#,P20#,P45#.

SHUNHAO Molds Factory always selects suitable mold steel for customers and customizes melamine press die according to the product requirements.

Shunhao Molds Factory has over 18 years of experience in melamine industry and will continue on the way to serve for more and more tableware factories.