Tel :

86-15905996312Email :

machine@hongancn.com

Tel :

86-15905996312Email :

machine@hongancn.comThe traditional tableware is ceramics or plastics. Ordinary plastics are easily damaged and polluted and are easily deformed by heat. While thermosetting melamine has many excellent properties: it can be colored easily, and it is not easy to fade or change color; it has good surface gloss with printed patterns, high hardness, acid and alkali corrosion resistance, not easy to damage and scratch; easy to clean, resistant to steaming, can be sterilized at high temperature; low thermal conductivity, good thermal insulation. It’s more and more popular in restaurants and daily life.

In recent years, the demand for melamine tableware in and out of China is increasing a lot, and the development prospect is broad. Melamine can also make sanitary ware.

The production process of melamine-formaldehyde resin is as follows:

Melamine + formaldehyde → reaction + filler → mixing → drying → crushing + mold release agent, dye, hardening catalyst → molding powder

For more details about the specific melamine tableware molding steps, we can go ahead to read the following.

1. Weighing

Accurately weigh the quantity of raw material required for each product. If the amount of raw material is too much or too little, it will cause more burrs, difficulty in polishing, insufficient molding pressure, and incomplete curing of products.

2. Preheating

Put the weighed raw material powder into the feeding container to preheat in the high frequency machine. The preheating time is generally 45-60 seconds, and the temperature of the material rises to 40~50℃.

3. Feeding

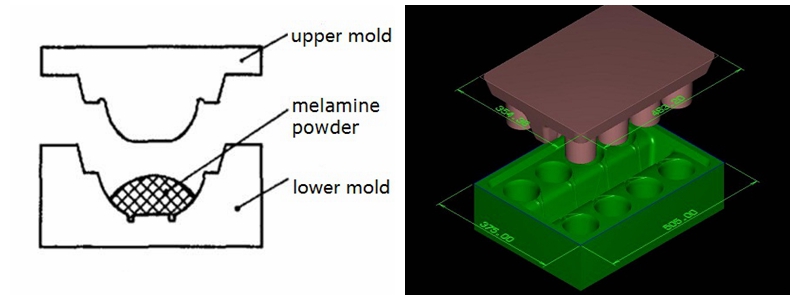

Put the preheated powder cake into a metal pressing mold (718# steel, chrome plated surface), and control the mold temperature between 150℃ and 180℃, which varies according to different products.

P.S. Click for details about How to choose melamine mold steel?

4. Curing Time

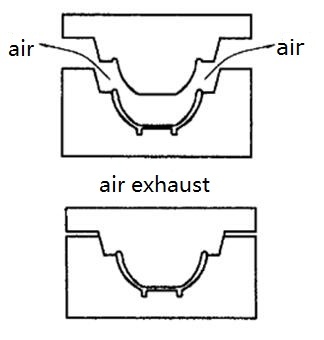

Pressurize the material by 5~15MPa for 1~15s. In this process, the material starts to flow along with the shape of the pressing mold under a certain temperature and pressure, and the polycondensation reaction occurs and water vapor is generated.

5. Air Exhaust

The generated condensation water and volatile gas (formaldehyde) are removed through the slightly opened mold gap.

6. Glazing

Spray the melamine glazing powder on the surface of the molded product, then continue to press the mold to 15~20MPa, 30~180s (depending on the product thickness adjustment), finally the product is molded.

7. Cleaning

After completing the glazing process, take out the product with suction cup and clean with an air gun, and last naturally cool the product.

8. Polishing &Packaging

For polishing, there are two ways: manual polishing and automatic polishing. The speed of automatic edging machine is 300-800 pieces per hour with the advantages of edging quality and saving labor. Just some special products such as cups, spoons, forks have to be polished by manual.

The above is a brief explanation of the steps of making melamine tableware. If you have more questions, please read other related articles in our website or directly contact us by CELL +86 15905996312

Shunhao Company is not only making the machines and molds for melamine tableware but also supplying one-stop-service with years experience.