Tel :

86-15905996312Email :

machine@hongancn.com

Tel :

86-15905996312Email :

machine@hongancn.com1. Widely used in preheating the raw material before melamine molding

2. Preheating can increase the melamine product yield

Brand:

Shunhaoitem no.:

HGY-720Payment:

LC, TTproduct origin:

ChinaColor:

Greenshipping port:

XiamenMachine Dimension:

600×850×1520MMMachine Weight:

320KGTrainning Service:

YesSupport Service:

Life-time ServiceFunction of High Frequency Preheating

The preheating process is widely used for thermosetting plastic molding, such as melamine tableware.

The high-frequency preheating which is using the principle of dielectric heating can make compression molding and other molding processes more efficient and trouble-free.

Preheating the melamine resin before molding helps to:

1. Reduce the cycle time to 1/2-1/5

2. Reduce the insufficient resin filling and air entrainment

3. Improve the yield and the insulation resistance

4. Improve other physical properties of the product strength

Principle of High-frequency Preheating

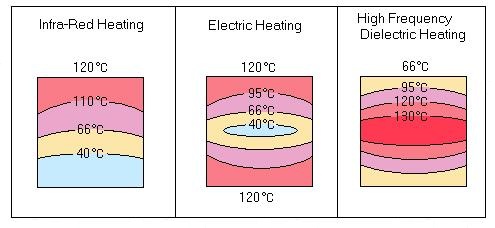

High frequency heating is internal heating, which means that the material itself generates heat due to molecular friction.

Electrical insulation materials such as plastics and wood generally have poor thermal conductivity. However, when a power of 3-100 MHz is applied to this material, it will force molecules (dipoles) to move up to 73*1,000,000 times at 73MHz, resulting in molecular friction and further rapid internal heat generation.

Technical Parameters

|

No |

Content. |

HGY-720 |

|

1 |

Output |

7KW |

|

2 |

Power Source |

3Φ220V 380V 415V |

|

3 |

Power Input |

13KVA |

|

4 |

Oscillation Frequency |

62MHZ |

|

5 |

Vacuum Tube |

E3069RB |

|

6 |

Voltage Switching |

3-stage |

|

7 |

Preheating Power |

110℃ Within 60 secs |

|

8 |

Phenolic Resin |

1500gr |

|

9 |

Melamine Moulding Compound |

1200gr |

|

10 |

Urea Moulding Compound |

1500gr |

■ PS: Specifications subject to change without notice.

Melamine Preheating Machine Maintenance

1. Dust and dust are often cleaned in the working room with a wind gun during use.

2. Periodically (at least once a month) use a wind gun to remove dust and impurities from the oscillation chamber, working room, and lower cabinet.

3. Periodically (at least once a month) wipe the electrode roller and edge plate in the working room with volatile solvent (such as toluene).

4. Periodically (at least once a week) check whether the contact between the phosphor copper sheet and the yellow horn copper around the upper cover is good. If there is blackening or oxidation, it should be polished in time.

5. Check regularly (at least once a week) whether the position of the connecting rod flywheel deviates. Under normal conditions: when the upper cover is closed, the flywheel hole is directly above; when the upper cover is opened, the flywheel hole is directly below. If it deviates, please adjust the corresponding micro switch in the chassis in time.

6. Periodically (at least once a week or month depending on site conditions) clean the air inlet filter of the whole machine.

7. After the power is turned on every day, turn off the "high voltage", and the machine runs a cycle working program without load before entering the work.