Tel :

86-15905996312Email :

machine@hongancn.com

Tel :

86-15905996312Email :

machine@hongancn.comToday, Shunhao Machine and Mould Factory is sharing the knowledge about electroplating which is an important step for compression molds making.

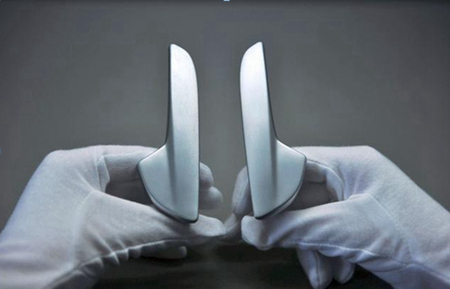

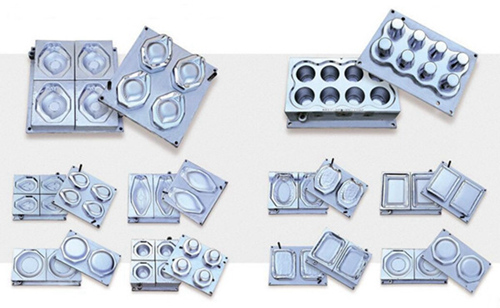

Shunhao brand melamine tableware moulds adopt chrome plating process. The mold has a higher flatness and metallic luster, which ensures that the products molded are easy to demold and have a high yield rate.

In mechanical design, electroplating is our most common part surface treatment process. Now let’s take a look at 5 common electroplating processes.

What is electroplating?

There are many methods of electroplating, and the type of electroplating varies with conditions such as material, location, and application. Electroplating mainly includes "wet electroplating" and "dry electroplating".

Wet Plating

Wet plating is a method that uses electrolysis and chemical reactions to put objects in a liquid for electroplating. It mainly includes electroplating (electrochemical plating) and chemical plating.

1. Electroplating (Electrochemical Plating)

A method of immersing metal ions in a solution containing metal ions to be electroplated, and depositing the metal ions on the metal surface through direct current electrolysis.

Chrome plating is one of the most commonly used electroplating because the plating layer has gloss, no discoloration in the air, low friction coefficient, good wear resistance, and good corrosion resistance.

2. Chemical Plating

Chemical plating refers to the deposition of metal ions on the surface of other materials by reacting the reducing substances and metal ions of the electroplating solution without using electrical energy.

The advantage of this method is that a relatively uniform film can be obtained regardless of the shape of the material, but it’s expensive.

Dry Electroplating

Dry electroplating includes vacuum electroplating, vapor electroplating (vapor deposition), and fusion electroplating using molten metal.

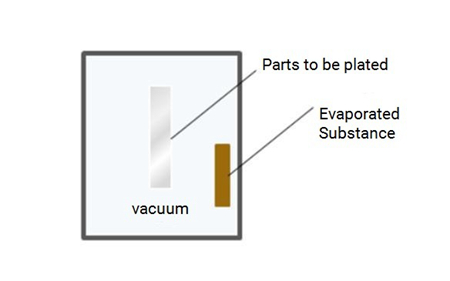

3. Vacuum Plating

Vacuum plating is a method of heating and evaporating metals or compounds in a high vacuum. By applying the evaporated atoms or molecules to the object to be plated, a thin film of the metal or compound is formed on the surface.

Industrial applications include decoration, wrapping paper, etc., depositing aluminum on metallic luster, as electrical applications, for resistors and capacitors.

4. Vapour Plating

The method of obtaining a metal coating by thermal decomposition or hydrogen reduction of metal halides and carbon-based compounds is called "gas phase plating". However, because the equipment is complex and costly, the working temperature is high, the materials need to be heated, and there are hazardous chemicals, it is only suitable for special fields.

5. Fused Plating

This is a method in which the object to be plated is immersed in a bath of molten metal and pulled upward to obtain the metal film on the surface.

The electroplating operation is very simple, and a thicker electroplated layer can be obtained in a short time, but its thickness cannot be freely controlled. Part of the material has also deteriorated.

Melamine dinnerware compression molds making from Shunhao is Electrochemical Plating, which is high cost and also high technology required.

To control the quality of the molds, chrome plating work is the last key to check. To make molds from Shunhao, your molds quality is guaranteed 100%!