Tel :

86-15905996312Email :

machine@hongancn.com

Tel :

86-15905996312Email :

machine@hongancn.comToday Shunhao Mould Factory will share the selection criteria of 718 mould steel for tableware factories and now announce the precious information to the public.

1. When the hardness requirements of the selected 718 mold steel are made, the hardness range that produces temper brittleness should also be avoided.

The first type of temper brittleness of carbon steel generally occurs at the lower limit of the above-mentioned temperature range, about 250°C, while that of alloy steel occurs at the upper limit temperature of about 350~300°C.

2. Considering from the perspective of preventing cracking, certain requirements should be put forward for the selection of materials.

Alloy steel has better harden ability and allows quenching in a slower cooling medium. The thermal stress and structural stress are relatively small, so the cracking tendency is also small. Carbon steel has poor harden ability and is prone to overheating. The structural stress and thermal stress during quenching are large, so the cracking tendency is also large.

3. The pursuit of the highest hardness value for the selected steel grade requires the designer to reasonably formulate practical technical conditions based on the service performance and the selected steel grade.

For the high cost or complex structure of the 718 steel mold, when the heat treatment is difficult to meet the technical requirements, the technical conditions should be temporarily changed, and those requirements that have little effect on the service life should be appropriately relaxed, so as to avoid multiple repairs and waste products. For those molds with complex forces and heavy loads during work, clear technical conditions should be put forward according to specific needs.

4. In addition, it is necessary to strengthen the inspection and management of raw materials to prevent 718 mold steel from cracking due to raw material defects.

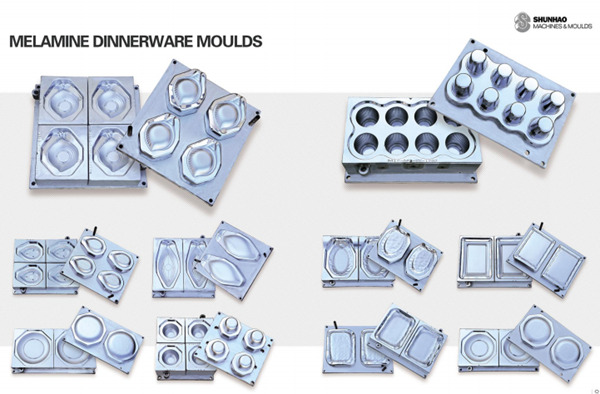

When select mold steel, Shunhao Melamine Molds Factory will comprehensively consider both technical and economic aspects, not only to meet technical requirements, but also to be economical and durable. 718 mold steel is the most popular type of steel used in melamine tableware factories.

Shunhao Mould Factory not only guarantees the quality and service life of the melamine press moulds in terms of technology and material selection, but also takes into account the production needs of tableware factories, which has won much trust and affirmation from customers.

For more information about the characteristics of 718 mold steel, melamine compress molds and other information, please consult online for free!

Contact Hot line: +86 15905996312