Tel :

86-15905996312Email :

machine@hongancn.com

Tel :

86-15905996312Email :

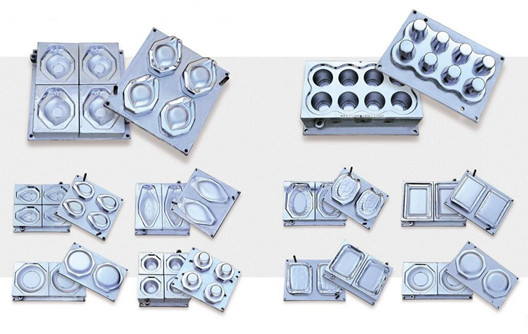

machine@hongancn.comMould is very important and indispensable special basic process equipment in industrial production. Without high-level molds, there will be no high-level industrial products. The level of the mold industry has become an important indicator to measure the level of a country's manufacturing industry.

Today Shunhao Factory (melamine molding machine and compress moulds manufacturer) will share with you about the reasons for mold damage. Hope it’s helpful for your factory production.

1. Mold temperature

The mold should be preheated to a certain temperature before production, otherwise, chilling will occur when the high-temperature molten metal is filled, which will increase the temperature gradient of the inner and outer layers of the mold, form thermal stress, and cause cracks or even cracks on the mold surface.

In the production process, the mold temperature continues to rise. When the mold temperature is overheated, it is easy to produce mold sticking, and the failure of moving parts causes damage to the mold surface.

2. Quality problems of rough forging

Some molds have cracks after only a few hundred pieces are produced, and the cracks develop very quickly. It is possible that only the external dimensions are guaranteed during forging, and the loose defects such as dendrites, carbide inclusions, shrinkage cavities, and air bubbles in the steel are extended and elongated along the processing method to form a streamline. This streamline affects the final quenching deformation, cracking, embrittlement during use, and failure tendency have a great influence.

3. Filling

The molten metal is filled with high pressure and high speed, which will inevitably produce fierce impact and erosion on the mold, thus generating mechanical and thermal stress. During the impact process, molten metal, impurities, and gas will also produce complex chemical interactions with the surface of the mold, and accelerate the generation of corrosion and cracks. When the molten metal is surrounded by gas, it will expand first in the low-pressure area in the cavity. When the gas pressure increases, inward blasting will occur, pulling out the metal particles on the surface of the cavity and causing damage and cracks due to cavitation.

Shunhao melamine compression molds are professionally designed from material selection, process, to structure. There will be a 3 Days Machine Testing before departure (non-stop running and pressuring) to ensure that the mold can work normally in the tableware factory.

In addition, if the machine fails to work, Shunhao's excellent engineers will provide you with online services and quickly solve the problem.

Mobile: +86 15905996312, Email:machine@hongancn.com