Tel :

86-15905996312Email :

machine@hongancn.com

Tel :

86-15905996312Email :

machine@hongancn.com

Shunhao

Factory offers good quality machines and dependable after-sales service. Below is

a straightforward guide to help you troubleshoot and maintain your automatic

melamine tableware polishing machine. If the material extraction system isn’t

functioning properly, follow these steps to identify and resolve the

problem.

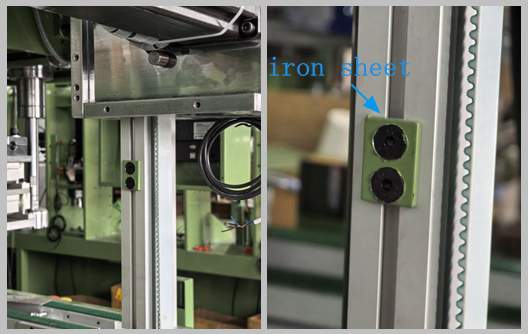

Step

1: Inspect the Iron Sheets on the Suction Rail

Examine

the two iron sheets located on the suction rail. These sheets interact with the

machine’s sensors, so proper alignment is essential.

Measure

the gap between the bottom of the iron sheet and the bottom of the copper sheet

on the suction assembly. The ideal measurement should be between 22 and 22.5

cm.

-

If the distance exceeds 22.5 cm, the material pick-up may be misaligned.

-

If it’s less than 22 cm, the suction assembly might collide with the top,

causing damage.

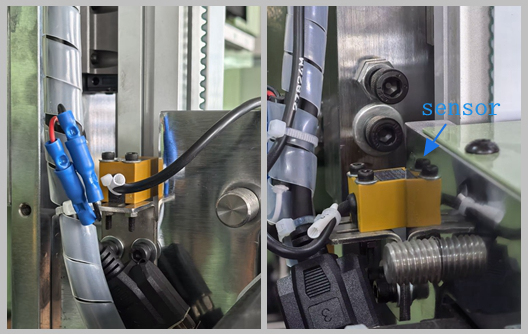

Step

2: Verify the Relay Functionality

Inspect the relay linked to the sensor. When the iron sheet rises during the extraction process (within the 22–22.5 cm range), the relay should activate and light up, confirming it’s operational.

-

If the relay fails to light up, it may be faulty and require replacement.

By following these steps, you can efficiently address material extraction issues and ensure your machine operates smoothly.

For

additional support, reach out to our customer service team—we’re always ready

to assist!

Contact Mobile: 86 159 0599 6312