Tel :

86-15905996312Email :

machine@hongancn.com

Tel :

86-15905996312Email :

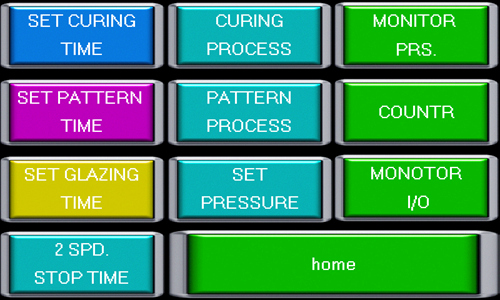

machine@hongancn.comWhen you look at the PLC, you may think so many parameters need to be adjusted; the production of melamine tableware seems to be a complicated production process.

However, after several months of operation, the important parameters can be summed up very easily.

1. Adjust the distance of rising and turning slowly before close the mold.

2. Adjust the molding time according to the size of the product.

3. Adjust the temperature. It’s adjusted according to different raw materials.

4. Adjustment of exhaust distance, exhaust wait, and exhaust time.

5. Adjustment of the decal time (almost the same, only fine-tuned).

6. Adjustment of the glazing powder time (almost the same, only fine-tuned).

Today Shunhao Factory will introduce the first one: The distance adjustment of the rising and slowing down before the mold is closed.

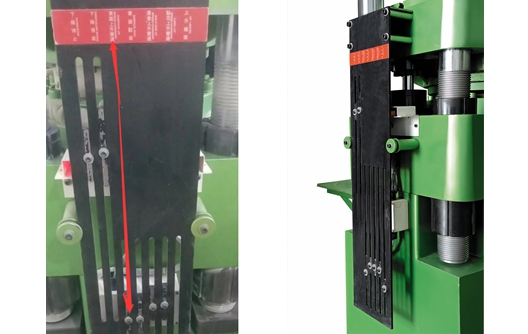

Firstly, look at the picture below, it can be adjusted on the stroke plate of the machine. There is a proximity sensor behind the stroke plate.

The button for rising and slowing down can be adjusted up and down.

a. When the button is close to the proximity sensor, and the light is on, indicating that the position starts to work from fast to slow.

b. After the raw material is on, the operator presses the CURING button, and then the machine starts to rise rapidly to close the mold. The operator adjust this button to decide where to turn slow.

Shunhao will continue to give some examples for you to know more clearly.

Plate Making

Raw materials run faster in plate mould then the button for rising and slowing speed can be adjusted downwards to close the mold as soon as possible.

Deep Bowl Making

Raw material needs more time to fill the entire cavity of the deep bowl mould, then the mold needs to be closed slowly, and the mold should be fully closed when the raw material has filled the entire cavity.

Therefore, those buttons on the stroke plate on the right side of the machine are very useful. We can fine-tune the action to make the machine and mold perfectly matched, which is also an advantage of extending the service life of the machine.

We hope this article is useful to you, please continue to support Shunhao Machine and Mould Factory!