Tel :

86-15905996312Email :

machine@hongancn.com

Tel :

86-15905996312Email :

machine@hongancn.comWhen we want to know much about the castings of the melamine machine, we must first understand the history of the cast iron.

According to the form of carbon in cast iron, cast iron can be divided into three types:

I. Gray Cast Iron

The carbon content is relatively high (2.7%~4.0%). The carbon mainly exists in the form of flake graphite with a gray fracture surface, referred to as gray iron. According to the different forms of graphite, gray cast iron can be divided into the following four types:

1. Ordinary gray cast iron. Low melting point (1145~1250℃), small shrinkage during solidification, compressive strength and hardness close to carbon steel, and good shock absorption. Due to the presence of flake graphite, it has good wear resistance. Casting performance and cutting processing are better. Used in the manufacture of structural parts such as machine bed, cylinder and box.

2. Malleable cast iron. Obtained from white cast iron after annealing treatment, graphite is distributed in clusters, referred to as tough iron. Its structure and properties are uniform, abrasion resistance, good plasticity and toughness. Used to manufacture parts with complex shapes and capable of withstanding strong dynamic loads.

3. Nodular cast iron. Gray cast iron molten iron is obtained after spheroidizing treatment, and the precipitated graphite is spherical, referred to as ductile iron. All or most of the carbon exists as free spherical graphite with a silver-gray fracture. Compared with ordinary gray cast iron, it has higher strength, better toughness and plasticity. Used in the manufacture of internal combustion engines, auto parts and agricultural machinery.

4. Vermicular graphite cast iron. The gray cast iron molten iron is obtained after vermicularization treatment, and the precipitated graphite is in the form of worms. The mechanical properties are similar to those of nodular cast iron, and the casting properties are between gray cast iron and nodular cast iron. Used in the manufacture of automotive parts.

II. White Cast Iron

The content of carbon and silicon is low, and the carbon mainly exists in the form of cementite, and the fracture is silvery white. Large shrinkage during solidification, easy to produce shrinkage holes and cracks. The hardness is high, the brittleness is big, can't bear the impact load. It is mostly used as blanks of malleable cast iron and making wear-resistant parts.

III. Alloy Cast Iron

Ordinary cast iron is obtained by adding appropriate amount of alloying elements (such as silicon, manganese, phosphorus, nickel, chromium, molybdenum, copper, aluminum, boron, vanadium, tin, etc.). Alloying elements change the matrix structure of cast iron, which has the corresponding characteristics of heat resistance, wear resistance, corrosion resistance, low temperature resistance or non-magnetic properties. Used in the manufacture of parts for mines, chemical machinery and instruments, meters, etc.

Casting Process

1. First of all, castings compete for the quality of the craftsmanship. If there is no good craftsmanship, no matter how good the raw materials are, no quality castings can be forged;

2. Secondly, castings are consumables, so that many consumers often only look at the appearance and ignore the craftsmanship when buying machine and equipment;

3. Thirdly, the quality of castings is generally impossible to judge with only eyes, it needs time to temper and verify. Qualified castings can generally be used for about 8 years.

4. If the workmanship and material do not meet the standards, the castings will wear out or rupture in about four years, resulting in the scrapping of the entire machine and equipment, and it will not work normally.

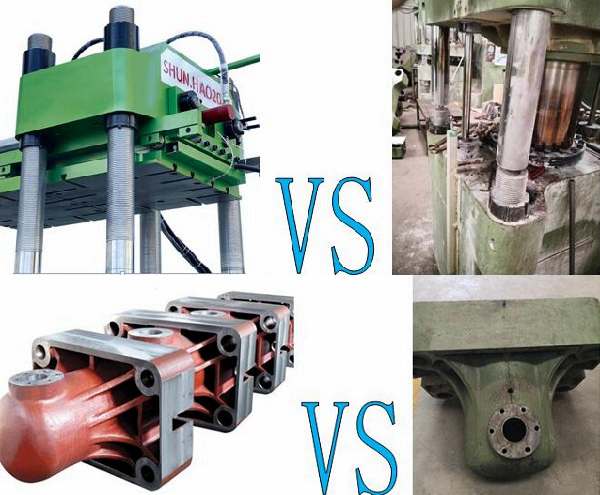

Melamine tableware compression machine produced by Shunhao uses nodular cast iron and is produced in Taiwan, China. It is a manufacturer with qualification certification and rich historical experience, ensuring the long time service life of large machinery.

Shunhao Machine has been committed to single and double color melamine tableware automatic pressing machine, melamine tableware automatic grinding machine, toilet seat lid making machine and various melamine crockery molds, urea toilet seat lid molds for over 18 years, with excellent technology and rich experience. Welcome to the tableware manufacturers and sanitary products manufacturers to visit our factory!