Today, Shunhao Machine Mould Factory has sorted out the common quality defects in thermosetting plastic molding and the reasons for product defects.

The following information can provide some experience references for thermosetting workers.

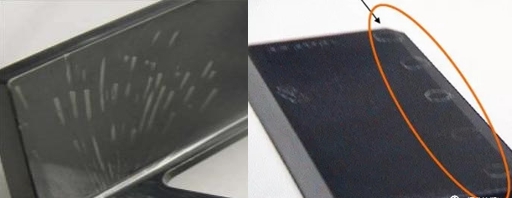

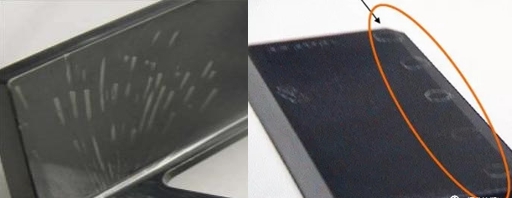

1. The surface of the plastic part is blistering or bulging

-

The content of moisture and volatile matter in the plastic exceeds the standard;

-

The mold is too hot or too cold; the mold pressure is insufficient;

-

Molding time is too short: plastic compression rate is too large, too much air contained, etc.

2. Plastic parts warpage

-

Insufficient degree of plastic curing;

-

The mold temperature is too high or the temperature difference between the convex and concave mold surfaces is too large, resulting in inconsistent shrinkage of various parts of the plastic part; the rigidity of the plastic part structure is not enough;

-

The wall thickness of the plastic part is uneven, and the irregular shape causes the material flow to solidify and cool unevenly, resulting in inconsistent shrinkage of all parts of the plastic part:

-

The fluidity of the plastic parts is too good;

-

The plastic stays in the mold for too long before closing the mold;

-

The content of moisture or volatile matter in the plastic is too large, etc.

3. Short injection or loose plastic parts

-

Insufficient pressure;

-

Insufficient feeding quantity;

-

The fluidity of the plastic is too good or bad;

-

The mold is closed too fast or the exhaust is too fast, causing the plastic to overflow from the mold;

-

The closing of the mold is too slow or the mold temperature is too high, so that some plastics are cured prematurely.

4. There are cracks in the plastic part

-

Improper volume ratio of insert to plastic or too many inserts

-

The structure of the insert is unreasonable

-

Unreasonable mold design or poor launch device

-

The wall thickness of the plastic part is too different

-

Excessive moisture and volatile content in plastics

-

The cooling time of the plastic part in the mold is too long, etc.

5. The surface of the plastic part is gray

-

The surface roughness of the mold is too low;

-

The lubricant is of poor quality or insufficient dosage;

-

The mold temperature is too high or too low, etc.

6. Spots or small seams appear on the surface of the plastic part

-

The plastic contains impurities, especially oily substances;

-

The mold is not well cleaned, etc.

7. Discoloration of plastic parts

8. Plastic parts sticking

-

There is no lubricant in the plastic or the amount is improper;

-

Low mold surface roughness.

9. Plastic part flash is too thick

-

Too much loading;

-

Plastic has poor fluidity;

-

Unreasonable mold design;

-

The guide sleeve is blocked, etc.

10. The surface of the plastic part is orange peel

-

The plastic mold closes too quickly under high pressure;

-

Plastic fluidity is too good;

-

The plastic particles are too coarse;

-

Excessive plastic water content, etc.

11. The plastic part is soft when it is demoulded

-

The degree of plastic curing is not enough;

-

Excessive plastic water content;

-

Too much lubricant on the mold, etc.

12. The size of the plastic part does not meet the requirements

-

The feeding amount is not accurate;

-

The size of the mold is not accurate or the wear is too large;

-

The plastic specifications do not meet the requirements, etc.

13. The electrical properties of plastic parts do not meet the requirements

-

Excessive plastic water content;

-

The degree of plastic curing is not enough;

-

Plastics contain metal contaminants or grease impurities.

14. Poor mechanical strength and chemical properties of plastic parts

-

The degree of plastic curing is not enough;

-

The mold temperature is too low;

-

Insufficient molding or insufficient feeding volume, etc.

As the old saying says, “A worker must first sharpen his tools if he wants to do well.”

Tableware factories must have the stable quality molding machine and the reasonable structure molds for melamine tableware production.

Shunhao is the manufacturer of urea and melamine machine and moulds that lots of customers home and abroad trust and cooperate for long development.

Quickly contact us for cooperation!

Mobile: 86+15905996312 Email: machine@hongancn.com