Tel :

+86-15905996312Email :

machine@hongancn.com

Tel :

+86-15905996312Email :

machine@hongancn.comMelamine tableware is a thermosetting plastic product, which is generally produced by compression molding.

Compression molding equipment is generally composed of the compression machine and the compression mold.

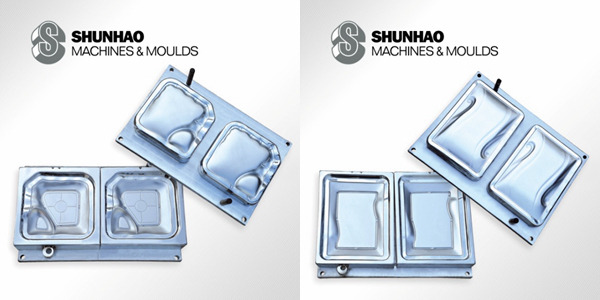

There are three types of moulds for compression molding. They are flash moulds, positive moulds and semi-positive moulds.

1. Flash Moulds

The flash mold has a simple structure and low manufacturing cost. The excess material can flash out during the pressing process, so the closing speed cannot be too slow. It is suitable for flat disc or butterfly shape products.

2. Positive Moulds

The structure of the positive mold is relatively complicated and the manufacturing cost is high. The two parts of the female mold and the male mold are required to be closed accurately. The operation technology requirements are high during pressing. The weight method must be used to feed, and it is not easy to vent, because the material cannot be removed from the cavity. All molding pressure acts on the material to obtain high-density products.

3. Semi-positive Moulds

The structure of the semi-positive mold is between the above two. Its manufacturing cost and operating requirements are lower than those of the positive mold. The material can flash out during pressing but is subject to certain restrictions. It can press some more complicated shapes products.

Two CNC machines were installed in Shunhao Factory in February 2020

Shunhao moulds are the flash type mold, and the finished product flash part must be trimmed off. However, the advanced CNC machines and very experienced mold designers and technicians make sure Shunhao moulds a longer service life and the least flash parts which will help more and more tableware factories to save cost and develop better in the future.