Tel :

86-15905996312Email :

machine@hongancn.com

Tel :

86-15905996312Email :

machine@hongancn.comIn industrial products, the production of various metals, plastics, rubber, glass, ceramics, powder metallurgy and conforming materials are inseparable from a good mold system. It can be said that the development of the mold manufacturing industry restricts the development level of various industries to a large extent.

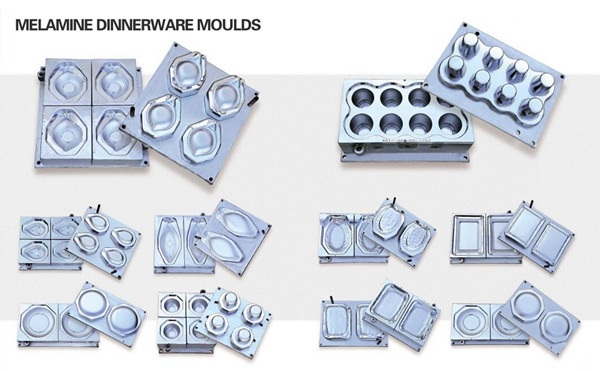

The quality and precision of melamine molds also determine the development level of melamine tableware factories.

Shunhao Mould Factory has more than 20 years of experience in making melamine press moulds, with advanced CNC equipment and an outstanding design and engineer team, and is committed to designing and producing high-quality melamine and urea moulds for tableware manufacturers home and abroad.

Today Shunhao will introduce the key points of die-casting mold structure design for your reference.

1. The mold should have sufficient rigidity and will not deform under the condition of withstanding the clamping force of the die-casting machine.

2. The mold should not be too bulky, it has been convenient for loading and unloading, repairing and handling, and reducing the load of the die-casting machine.

3. The pressure center of the mold cavity should be as close as possible to the center of the clamping force of the die-casting machine to prevent uneven force on the die-casting machine, resulting in inadequate clamping of the mold and burrs on the casting.

4. The shape of the mold should be considered to match the specifications of the die-casting machine.