Tel :

86-15905996312Email :

machine@hongancn.com

Tel :

86-15905996312Email :

machine@hongancn.com1. Preheatin can improve product qualification rate

2. Preheating can increase the production efficiency

Brand:

Shunhaoitem no.:

HGY-720Payment:

LC, TTproduct origin:

ChinaColor:

Greenshipping port:

XiamenMachine Dimension:

600×850×1520MMMachine Weight:

320KGTrainning Service:

YesSupport Service:

Life-time ServiceFunction of High Frequency Preheating

Make compression molding and other molding processes more efficient and trouble-free.

Preheating the melamine resin before molding helps to:

1. Reduce the cycle time to 1/2-1/5

2. Reduce the insufficient resin filling and air entrainment

3. Improve the yield and the insulation resistance

4. Improve other physical properties of the product strength

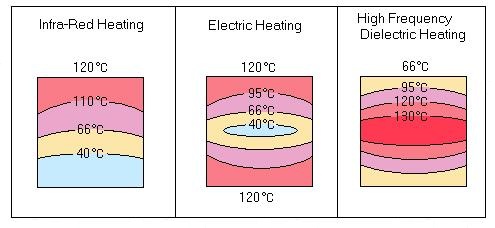

HIGH FREQUENCY DIELECTRIC HEATING THEORY

Wood, rubber, synthetic resin, and other materials having a high DC and AC electrical resistance are rapidly heated when placed in a high-frequency electric field. This phenomenon is based on the following theory.

Materials having few free electrons are generally known as the dielectric material. The molecules of these materials have a fixed polarity (+) or (-) electric charge. This polarity is electrically vibrated by high-frequency polarity switching.

The electrical energy produced in this manner is converted to heat energy and heat is generated within the body of the dielectric material itself.

The amount of heat generated during one second is directly proportional to heat generated high-frequency source, but frequency of 1MHz (1, 000,000Hz) is normally required to generate heat.

Technical Parameters

|

No |

Content. |

HGY-720 |

|

1 |

Output |

7KW |

|

2 |

Power Source |

3Φ220V 380V 415V |

|

3 |

Power Input |

13KVA |

|

4 |

Oscillation Frequency |

62MHZ |

|

5 |

Vacuum Tube |

E3069RB |

|

6 |

Voltage Switching |

3-stage |

|

7 |

Preheating Power |

110℃ Within 60 secs |

|

8 |

Phenolic Resin |

1500gr |

|

9 |

Melamine Moulding Compound |

1200gr |

|

10 |

Urea Moulding Compound |

1500gr |

■ PS: Specifications subject to change without notice.